ENABLING ENVIRONMENTS WHERE INNOVATION THRIVES

Edwards is at the forefront in the design and manufacture of EUV Fab support equipment, driving efficiency and innovation at every opportunity.

The process of extreme ultraviolet lithography, or EUV, is technology that leading semiconductor chipmakers use in the manufacturing of the most advanced components. The pressing challenge is always tool uptime and we are constantly innovating our integrated, SubFab systems to deliver on performance across all benchmarks.

As the driving innovator in the space for 20 years, Edwards has established an install base of more than 150 systems. Clearly the most experienced in EUV solutions we are uniquely placed with a deep data history and global service support to face any challenge.

Meeting our EUV customers’ challenges

Maximising productivity

Our EUV lithography support systems are a combination of pumping power and abatement units designed to work together at maximum efficiency to evacuate and abate unwanted gases during the processes of EUV semiconductor manufacture. Maximising productivity means understanding the increasingly complex demands from EUV lithography. In fact, tool availability and output drives our innovation. For example, our recent upgrade delivers greater system power and serviceability with reduced energy demand and emissions.

Sustainability

There are greater commercial expectations today for semiconductors to be manufactured in a sustainable and accountable way. This, while still meeting growth and chamber productivity demands. Sustainability impacts our design process. Taking just one example, Edwards current EUV upgrade delivers an average CO2 reduction per system of 270,000kg pa.

Global expertise locally applied

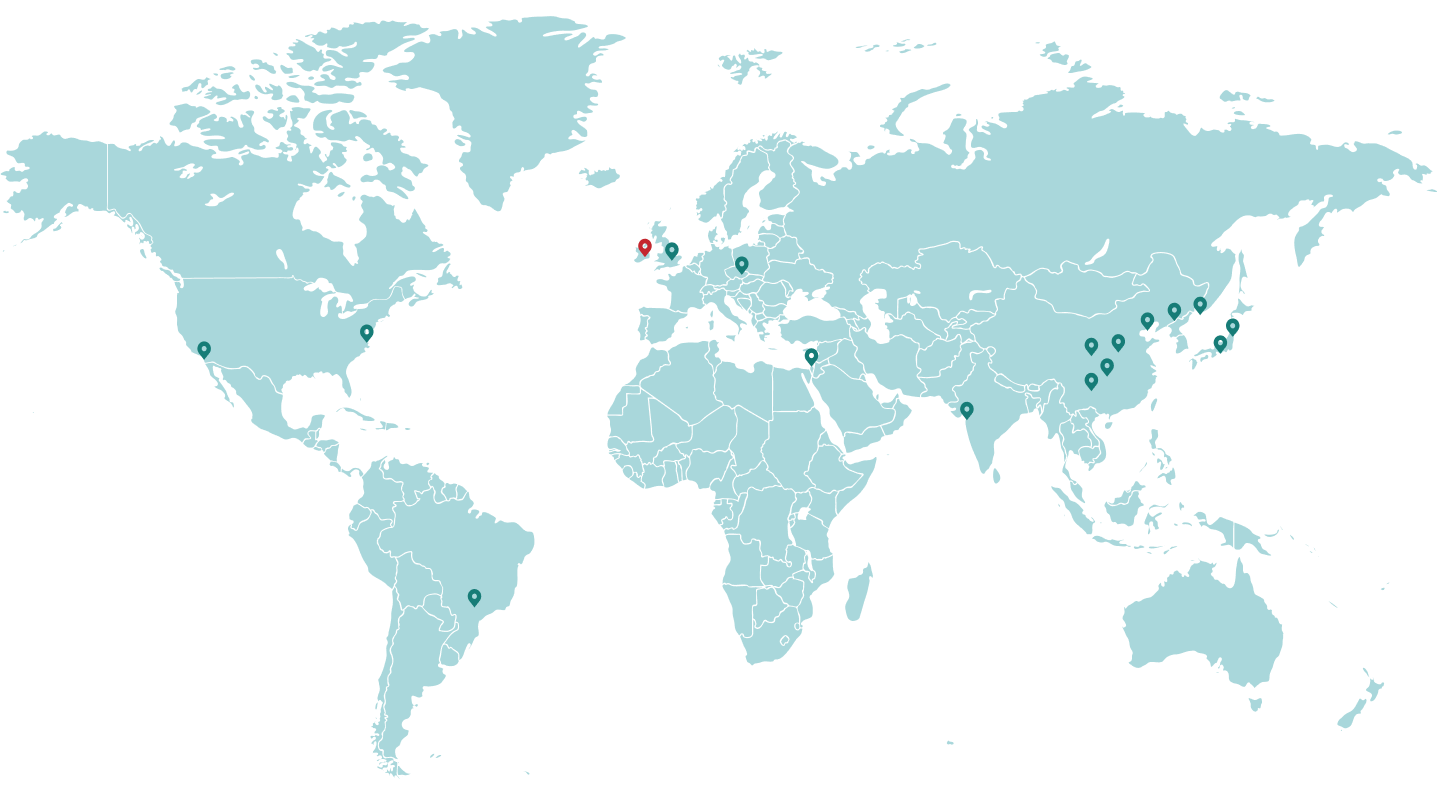

Edwards is uniquely positioned to support our global customers with local solutions employing our 20 years of data and performance analytics. This is gained from the world's largest system install base and the service experience that goes with it. Our global network of Service Centres, engineers and experts means our customers always have the support they need based on actual information.

Safety

The growing volumes of flammable hydrogen employed means we design-in safety wherever possible. The Edwards solution includes system monitoring to ensure the continued safe operation of both the EUV Tool and each Edwards system.

Watch now: Maximising productivity in EUV

Edwards EUV Lithography

The future of EUV, what our experts are saying

Our new EUV upgrades deliver to your productivity and environmental goals with enhanced TCoO

See how our EUV upgrades are making an impact for one Edwards customer. Choose either the interactive story or a PDF

To read more about these challenges, David Engerran’s interactive paper on EUV is available to download for desktop and mobile below.