Vacuum Solutions for Plastic Industry - Brochure

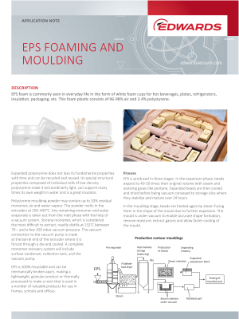

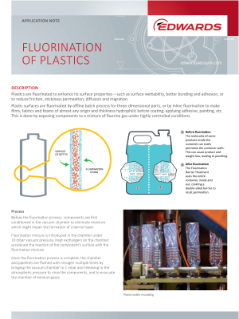

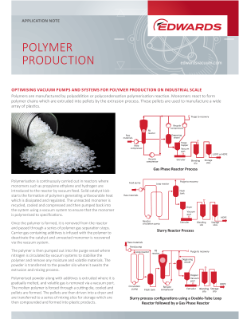

Vacuum pumps are widely applied in processing plastics and composite manufacturing, mainly to extract gases and vapours and to operate at lower processing temperatures. Production of high-quality everyday thermoplastics with lower environmental impact has become a necessity.

Edwards vacuum systems can play a significant role in helping you to drive up your product quality and throughput with new levels of reliability, flexibility and profitability. Our vacuum pumps have been successfully supporting the plastics circular economy at every step of plastics lifecycle.

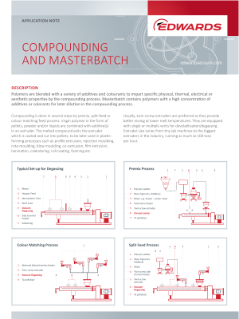

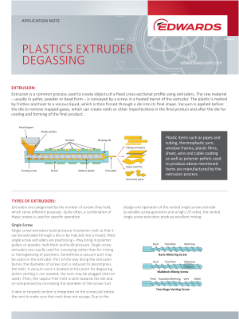

Vacuum pumps play an important role in degassing plastics as water vapour, toxic and corrosive gases and other impurities affect the quality of the product. Polymer melts are degassed to remove these impurities at low pressures using vacuum pumps on extruders when being compounded into different grades with additives and colorants and while being formed.

When high quality plastics are manufactured, vacuum pumps become one of the key tooling components on the extruder especially employed during processes like:

Various plastic recycling methods make use of vacuum systems to remove entrained gases and aid the reaction in solid state recycling of PET, HDPE, LDPE, PC, ABS and even in liquid state recycling process for PET. With the advances in plastics recycling methods, our vacuum pumps have proven to be a critical piece of equipment for recycling plastics to a higher purity standard.

Composites are made by combining two materials having different properties, a reinforcement (fiberglass, carbon fibre, aramid fibre) with a resin matrix which is another name for polymer. With this combination, you get the best of both worlds, strength from the fibre and the unique benefits from polymer (corrosion resistant, heat resistant, lightweight).

Composites can be manufactured using various open or closed methods depending on attributes, shape of the end product, production volume and usually with the aid of vacuum pumps.

Our expertise in vacuum applications allow us to design and deliver robust and reliable vacuum systems to meet your vacuum needs in plastics and composites manufacturing processes.

Edwards vacuum for the plastics industry

Edwards Extruder degassing module for the plastics industry