nEXT M Maglev Turbo Pumps - Digital Brochure

nEXT M pumps are one of the lightest and most compact Maglev turbo pumps available on the market in the 3,000 l/s pumping class, making them an excellent choice for coating applications as well as research and industrial processes.

Providing the clean and stable environments critical for precise operations, the nEXT M Maglev pumps are not only reliable but also maintenance-free for up to 10,000 cycles.

Magnetically levitated turbo pumps, also known as Mag or Maglev pumps, are based on the highly successful mechanical turbomolecular vacuum technology.

The principal difference between mechanical and magnetically levitated turbomolecular pumps is that the ‘rotor’ and ‘stator’ blades are held in position by precision made magnets rather than oil-lubricated bearing systems.

This means they produce minimal levels of friction and vibration, and cleaner, contamination-free vacuum performance making them ideal for processes such as coating.

The electromagnetic bearings also make them suitable for harsh industrial environments as they are able to withstand mechanical-shocks as well as exposure to dust and moisture.

But what makes the nEXT M range really stand out is their versatility.

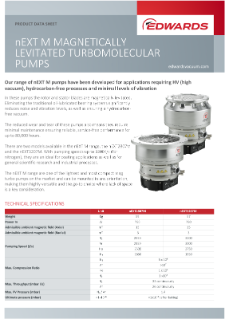

nEXT 2807M turbomolecular pump

nEXT 3207M turbomolecular pump

nEXT M Pumps are ideally suited for sensitive processes, as well as in challenging industrial environments:

Coating

covering thousands of products from glass lenses, surgical instruments and solar panels to aerospace components and telescopic lenses used in astronomy

Scientific research

from simulated space environments to particle accelerators and fusion research

Industrial

Furnace welding applications and precision-made machine parts

Hydrocarbon-free performance, resilience, reliability and low levels of vibration.

Up to 80,000 hours, or 10,000 start/stop cycles of maintenance-free performance.

Coating applications require stable environments with minimal levels of vibration.

Efficient cooling of the pump is achieved through a water-cooling process via the inlet/outlet ports on the pump.

The nEXT 2807M has a pumping speed of up to 2,500 l/s and the nEXT 3207M has a pumping speed of up to 3,200 l/s.

From expert repairs to smart service plans, genuine parts, remote diagnostics, and even buyback—our all-in-one vacuum care keeps your systems running at their best.